| Sign In | Join Free | My ccnmag.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My ccnmag.com |

|

Brand Name : KECHENG

Model Number : KC-D/920/1224/1228/1632

Certification : CE certification

Place of Origin : China

MOQ : 1 sets

Price : Negotiated

Payment Terms : L/C,TT

Supply Ability : 200 sets per year

Delivery Time : 65 working days

Packaging Details : Plastic film packaging and cartons

Name : Automatic Control Printer Slotter Die Cutter

Application : Carton printing slotting die cutting

Cardboard type : Corrugated cardboard

Power : 380V,50HZ or 440V

Speed : 200pcs/min

Max Feeding size : 900*2000mm-1600*3200mm

Min feeding size : 280*650mm-450*720mm

Wall thickness : 50mm/60mm/70mm

Anvil cover : Depair or Maxdura

Operation : Automatic

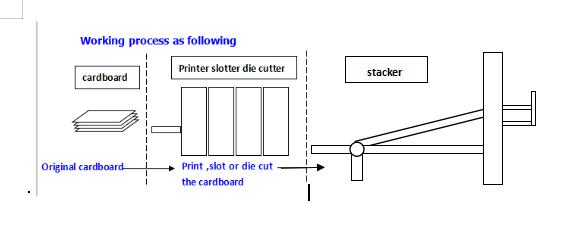

High Performance Automatic Control 5 Color Printer Slotter Die Cutter

Automatic Control 5 Color Printer Slotter Die Cutter main features as following

1) Each unit can be moved

2) Lead edge feeder

3) Emergency stop for safe control installed on each unit

4) Automatic washing sytem at the printing unit.

5) Roller transfer or vacuum transfer option at printing unit

6)easy to operate and maintain.

Printer slotter die cutter as the important machine for making the carton, we have different models for choice. Automatic high speed,semi automatic,vacuum transfer ,roller transfer, no matter what kind of machine, we will give one year quality gurantee.

Technologic parameter of printer slotter machine

| Model | KC-D 920 | KC-D1224 | KC-D1632 |

| Max feeding size | 900*2100mm | 1200*2500mm | 1600*3300mm |

| Min feeding size | 300*650mm | 400*720mm | 450*750mm |

| Max printing size | 880*1000mm | 1150*2400mm | 1550*3200mm |

| Skip feeding size | 1100*2100mm | 1400*2500mm | 1800*3300mm |

| Max speed | 300pcs/min | 220pcs/min | 180pcs/min |

| Registering | +/-0.5mm | +/-0.5mm | +/-0.5mm |

| Min slotting gap | 250*70*250*70m | 270*80*270*80mm | 280*100*280*100mm |

Eech unit features

Feeder unit

• Lead edge feeder suction pressure can be adjusted according to different cardboard,making the feeding easily and smooth

• Continuous feeding and skip feeding are available.

• All the baffle adjusted by electric control.

• Linear guide rail and screw shaft make the baffle easily and accurately.

• Alarm will sound when move the each unit for warning .

• Dedust suction blower remove the dust on the surface of cardboard

• Main motor and blower adjusted by inverter control

Printer unit

• Top printing,vacuum transfer or roller transfer for option.

• Rollers plated with rigid chrome,grinded surface and undergoes balance treatment

• Rachet printing plate fix device make the printing more precise

• Rubber roller with steel anilox ink distribution for option

• Doctor blade with ceramic anilox roller ink distribution

• Close type doctor blade system and innovated ink-closed design to make the ink distribution very well, save ink.

• Pneumatic lock, doctor blade compensition structure to make the ceramic roller touch with doctor well for good ink distribution effect.

• Automatic reposition after washing the printing template during the printing procession.

• Automatic ink washing system.

Slotter unit

• Double shaft slotting unit consists of pre creasing wheel, first slotting, creasing wheel and second slotting

• Creasing wheel with PU Plated for good creasing and avoiding paper crack

• Auto zero- set for slotting knife with one push button.

• Pre creasing roller and creasing roller gap adjusted by touch screen control

• Cast steel slotting guide plates makes slotting precise and never damage the slotting knife.

• All the knives move and slotting holder move adjusted by PLC control

Die cutter unit

|

|

Automatic Control 5 Color 200pcs/Min Printer Slotter Die Cutter Images |